Quickly Analyze Thick, Large Sample Materials

Designed for use in the steel, automotive, electronics, and other manufacturing industries, the GX53 microscope delivers crisp images that can be difficult to capture using conventional microscopy observation methods. When combined with PRECiV image analysis software, the microscope streamlines the inspection process from observation to image analysis and reporting.

Fast Inspections, Advanced Functionality

Quickly observe, measure, and analyze metallurgical structures.

Advanced Analysis Tools

1. Combined observation methods produce exceptional images

2. Easily create panoramic images

3. Create all-in-focus images

4. Capture both bright and dark areas

Optimized for Material Science

1. Software designed for materials science

2. Metallurgical analysis that complies with industrial standards

User Friendly

Even novice operators can comfortably make observations, analyze results, and create reports.

1. Easily restore microscope settings

2. User guidance helps simplify advanced analysis

3. Efficient report generation

Advanced Imaging Technology

Our proven optics and imaging technology deliver clear images and reliable results.

1. Reliable optical performance: wavefront aberration control

2. Clear images: image shading correction

3. Consistent color temperature: high-intensity white LED illumination

4. Precise measurements: auto calibration

Modular

Choose the components you need for your application.

1. Build your system your way: fully customizable system with a variety of optional components

Advanced Analysis Tools

The GX53 microscope’s various observation capabilities provide clear, sharp images, so you can reliably detect defects in your samples. PRECiV image analysis software's new illumination techniques and image acquisition options give you more choices for evaluating your samples and documenting your findings.

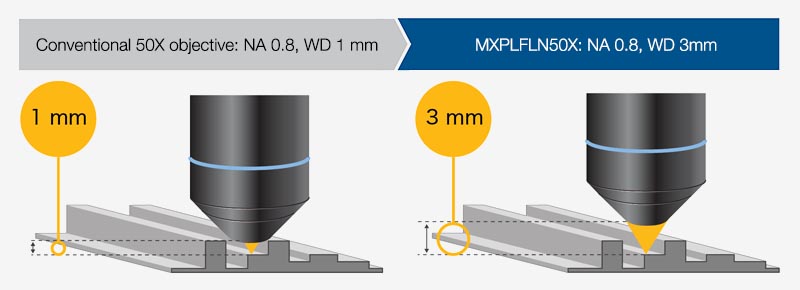

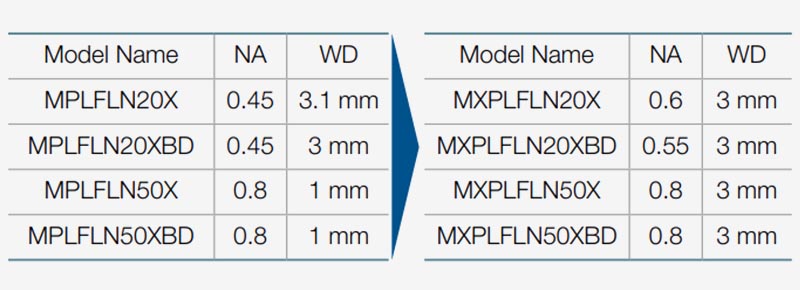

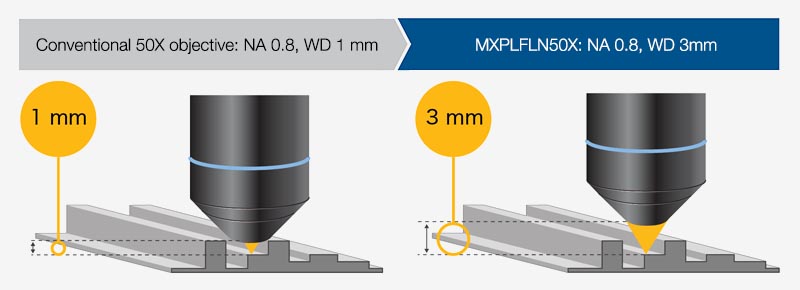

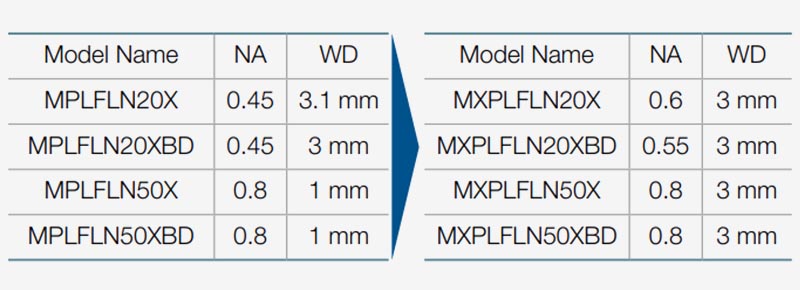

Combined high numerical aperture and long working distance

Objective lenses are crucial to a microscope’s performance. The new MXPLFLN objectives add depth to the MPLFLN series for epi-illumination imaging by maximizing numerical aperture and working distance at the same time. Higher resolutions at 20X and 50X magnifications typically mean shorter working distances, which forces the sample or objective to be retracted during objective exchange. In many cases, the MXPLFLN series’ 3 mm working distance eliminates this problem, enabling faster inspections with less chance of the objective hitting the sample.

The Invisible Becomes Visible: MIX Technology

MIX technology combines darkfield with another observation method, such as brightfield or polarization, to enable you to view samples that are difficult to see with conventional microscopes. The circular LED illuminator has a directional darkfield function where one or more quadrants are illuminated at a given time, reducing a sample’s halation to better visualize surface texture.

Cross-section of a printed circuit board

|

|

|

|

|

|

|

|

|

Brightfield

The substrate layers

and through

hole are invisible.

|

|

Darkfield

The traces

are invisible.

|

|

MIX: Brightfield + Darkfield

All of the components

are clearly represented.

|

|

Stainless steel

|

|

|

.jpg)

|

|

|

|

|

|

Brightfield

The texture is

unobservable.

|

|

Darkfield quadrant

The color information

is eliminated.

|

|

MIX: Brightfield + Darkfield quadrant

Both the material color

and texture are visible.

|

|

Easily Create Panoramic Images: Instant MIA

With multiple image alignment (MIA), you can stitch images together simply by moving the XY knobs on the manual stage—a motorized stage is optional. PRECiV software uses pattern recognition to generate a panoramic image, making it ideal for inspecting carburizing and metal flow conditions.

Metal flow of a bolt

|

|

|

|

|

|

|

|

|

Adjust the stage

position using

the XY knob.

|

|

|

|

The full condition of

metal flow can be seen.

|

|

Create All-in-Focus Images: EFI

PRECiV software’s extended focus imaging (EFI) function captures images of samples whose height extends beyond the depth of focus. EFI stacks these images together to create a single all-in-focus image of the sample. Even when analyzing a cross-section sample with an uneven surface, EFI creates fully-focused images.

EFI works with either a manual or motorized Z-axis and creates a height map to visualize structures.

Resin parts

|

|

|

|

|

|

|

|

|

Adjust the objective's

height with the

focusing handle.

|

|

EFI automatically captures

and stacksmultiple images

to create a single,in-focus

image of the sample.

|

|

Fully focused image is created.

|

|

Capture Both Bright and Dark Areas Using HDR

Using advanced image processing, high dynamic range (HDR) adjusts for differences in brightness within an image to reduce glare. It also helps boost the contrast in low-contrast images. HDR can be used to observe minute structures in electric devices and identify metallic grain boundaries.

Gold plate

|

|

|

|

|

|

| Some areas have glare. |

|

Both dark and bright areas are

clearly exposed using HDR.

|

Chromium diffusion coating

|

|

|

|

|

|

| Low contrast and unclear. |

|

Enhanced contrast with HDR. |

Applications

There are just a few examples of what can be achieved using different observation methods.

Polished sample of AlSi (Brightfield / Darkfield)

Brightfield: a common observation method to observe reflected light from a sample by illuminating it straight on.

Darkfield: observe scattered or diffracted light from a sample, so imperfections, such as minute scratches or flaws, clearly stand out.

Spheroidal graphite cast iron (Brightfield / DIC)

|

|

|

|

|

|

| Brightfield |

|

DIC observation |

|

Differential interference contrast (DIC): an observation technique where the height of a sample is visible as a relief, similar to a 3D image with improved contrast;

it is ideal for inspections of samples that have very minute height differences, including metallurgical structures and minerals.

Aluminum alloy (Brightfield / Polarized light)

|

|

|

|

|

|

| Brightfield |

|

Polarized light observation |

|

Polarized light: a technique that highlights a material's texture and crystal condition to view metallurgical structures,

such as the growth pattern of graphite on nodular cast iron and minerals.

Electric device (Brightfield / MIX observation)

|

|

|

|

|

|

| Brightfield |

|

MIX: Brightfield + Darkfield |

|

MIX observation: combines brightfield and darkfield to show a sample's color and structure.

The above MIX observation image clearly reproduces the device’s color and texture as well as the condition of the adhesive layer.

GX53_Brochure_CN

GX53_Brochure_CN

GX53_Brochure_EN

GX53_Brochure_EN

Microsystem

Microsystem Endoscopysystem

Endoscopysystem Energysystem

Energysystem EndoscopyConsumables

EndoscopyConsumables +86-21-54286005

+86-21-54286005

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China

Room 602, Building 1, No. 111 Luxiang Road (Greenland Park Plaza), Baoshan District, Shanghai, China  English

English

中文

中文

.jpg)

.jpg)

中文

中文 English

English